Problem Solving is an Art

In business, problem-solving is a part of everyday life. Unfortunately, while the size and scope of each issue may change, their existence remains the same. It is this realization that recently prompted our management team to fundamentally change the way we look at the problem. Not just how you deal with them, but more importantly how you see them and even talk about them.

We are now energized and focused on being very good at problem-solving technology. As management, we are committed to being highly specialized and competent problem solvers in our respective areas of responsibility. We believe that while you travel with us, you will enjoy seeing all the hard work of our extraordinary problem-solving team as much as we enjoy putting it into practice.

We are now energized and focused on being very good at problem-solving technology. As management, we are committed to being highly specialized and competent problem solvers in our respective areas of responsibility. We believe that while you travel with us, you will enjoy seeing all the hard work of our extraordinary problem-solving team as much as we enjoy putting it into practice.

Raw Stores

Recently, a live central feeding system was added to our raw stores, allowing us to better manage our raw materials and store the stock by type in batches.

IMM Plants

Our first four injection moulding machines have been relocated to IMM Plant 3. They are currently up and running.

Toolroom

The gantry for our toolroom has been set up. This will increase productivity while ensuring a safer working environment for our employees and assets.

Assembly

Our assembly factory now has a mezzanine floor, allowing for a dedicated location for the assembly of small components. The space below the mezzanine has been designated as an assembly component store, which will enhance traceability and assembly procedures.

Distribution

To make it simple for customers to recognize our fleet when making deliveries, we are changing the branding on our vehicles. To ensure that goods are handled carefully while in transportation, our highly skilled drivers are sent for the necessary training.

D & E

We have three vibrant meeting places in our Think Tank Studio that were created as creative spaces for you to visit, enjoy a delicious cup of coffee, and allow us to assist you in making your idea a reality.

Systems

Our ERP manufacturing module has been relaunched, enabling us to swiftly and precisely trace product movement throughout our factories using a barcoding and scanning technology.

Quality

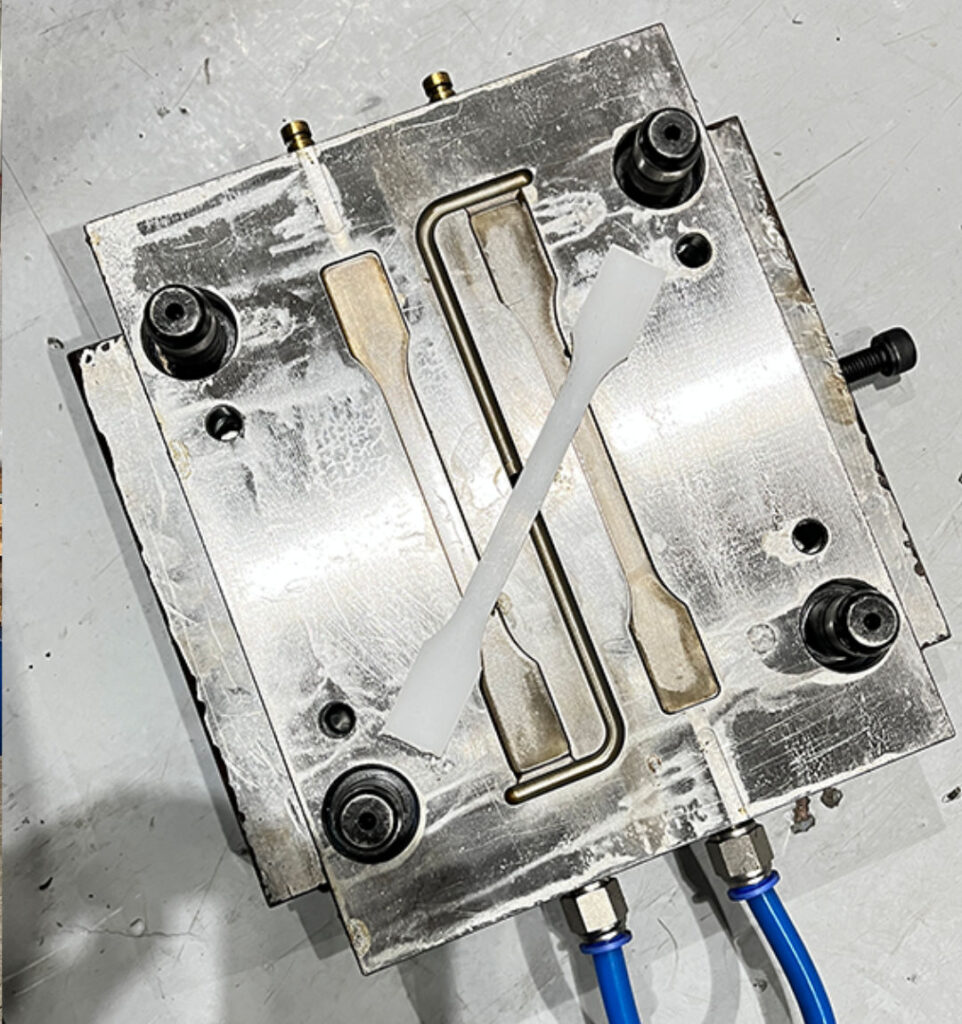

In order to create samples of supplied material for testing tensile and compression strength, we designed a dog-bone mould. This enables us to assess whether the material’s strength complies with the necessary requirements.

Culture

Our management team participated in the King Price Culture Tour, and as a result, we have been greatly inspired by them and are putting some of their incredible fundamental principles into practice in our company.