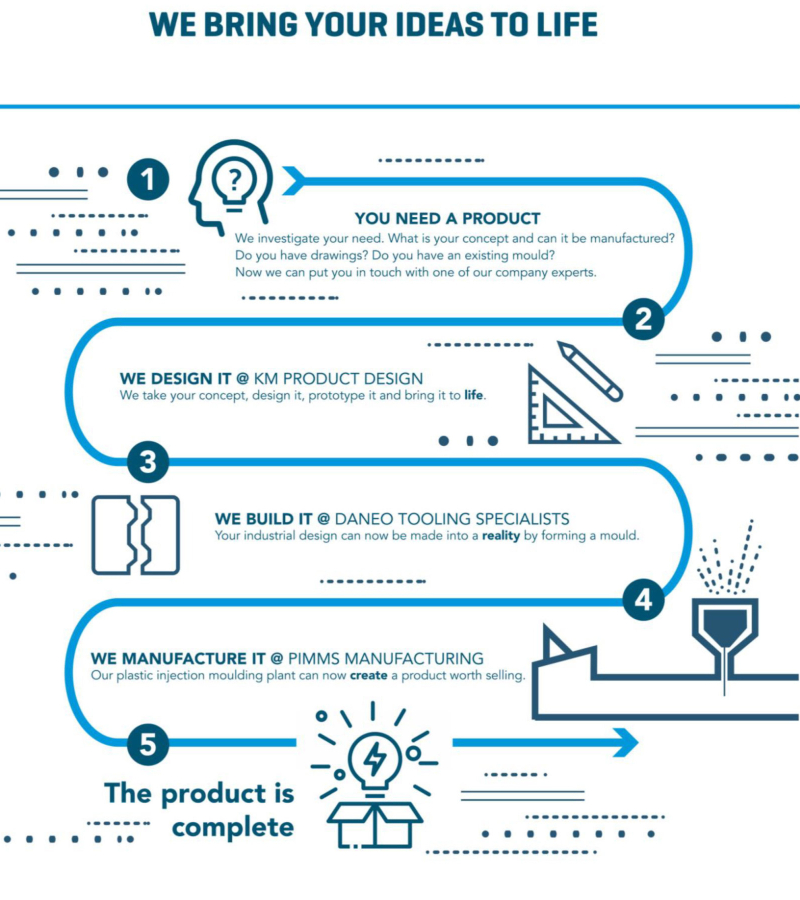

We bring your Ideas to Life through world class processes

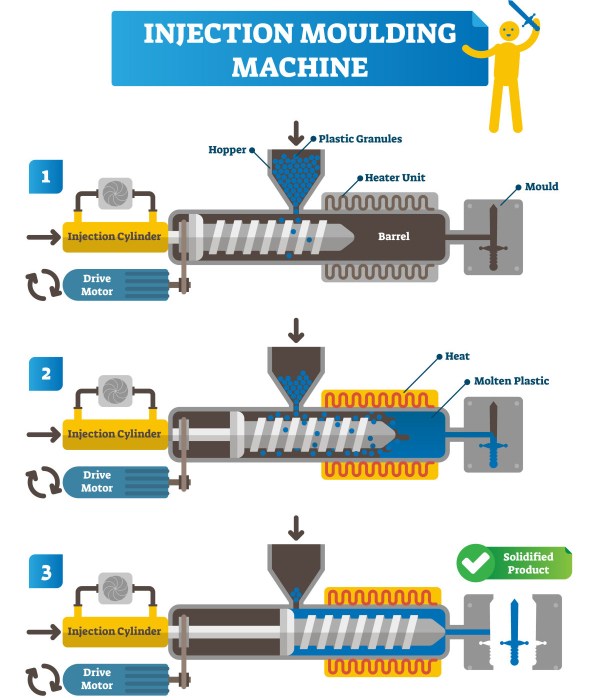

What is Injection Moulding?

Injection moulding is the manufacturing process whereby molten plastic pellets are injected into a mould in order to form particular parts.

How Injection Moulding Works

After a product gets designed by an industrial designer or engineer, a toolmaker will then proceed to make a mould from steel or aluminium which will be utilized for manufacturing.

Plastic pellets begin in a hopper where gravity forces them into a heating barrel. Inside, a combination of pressure and heating elements melt the plastic to the required temperature. The molten plastic is then forced into the mould cavity where it is then cooled and solidifies into the shape of the cavity. The mould opens and the part is ejected out of the mould. This process is then repeated. A variety of different size components can be manufactured using various materials including commodity plastics, engineering polymers and high-performance polymers.

Injection Moulding is the perfect solution when you need to replicate a particular plastic part, thousands or even millions of times.

There are 3 main costs involved

in developing a product

The Cost of the Design

The Cost of the Mould

The Cost of Manufacturing the Parts

Factors which contribute to the Cost of the Part includes

- The size and weight of the part

- The complexity of the part

- The number of cavities the mould has

- The material used to make the part

- The quantity you require

For more information on designing a product or mould prices please do not hesitate to contact us.